The world of pure white UCHIYAMA GAMI

純白の雪にある「内山紙」の世界

Japanese paper has been longly rooted in Japanese life. While there are various Japanese paper producing regions throughout Japan, in Nagano Prefecture there is a unique type of paper called ‘Uchiyama paper’ that is made by a manufacturing method specific to the type of paper. Uchiyama Paper is made of 100% Kozo paper mulberry (the bark of the tree Japanese paper is produced from) and is crafted by hand. Therefore, it is not only very tough but also surprisingly smooth, high-class Japanese paper compared to other ordinary Japanese papers. Every single Uchiyama paper is carefully created by hand, with time and effort, from natural materials sourced from the region.

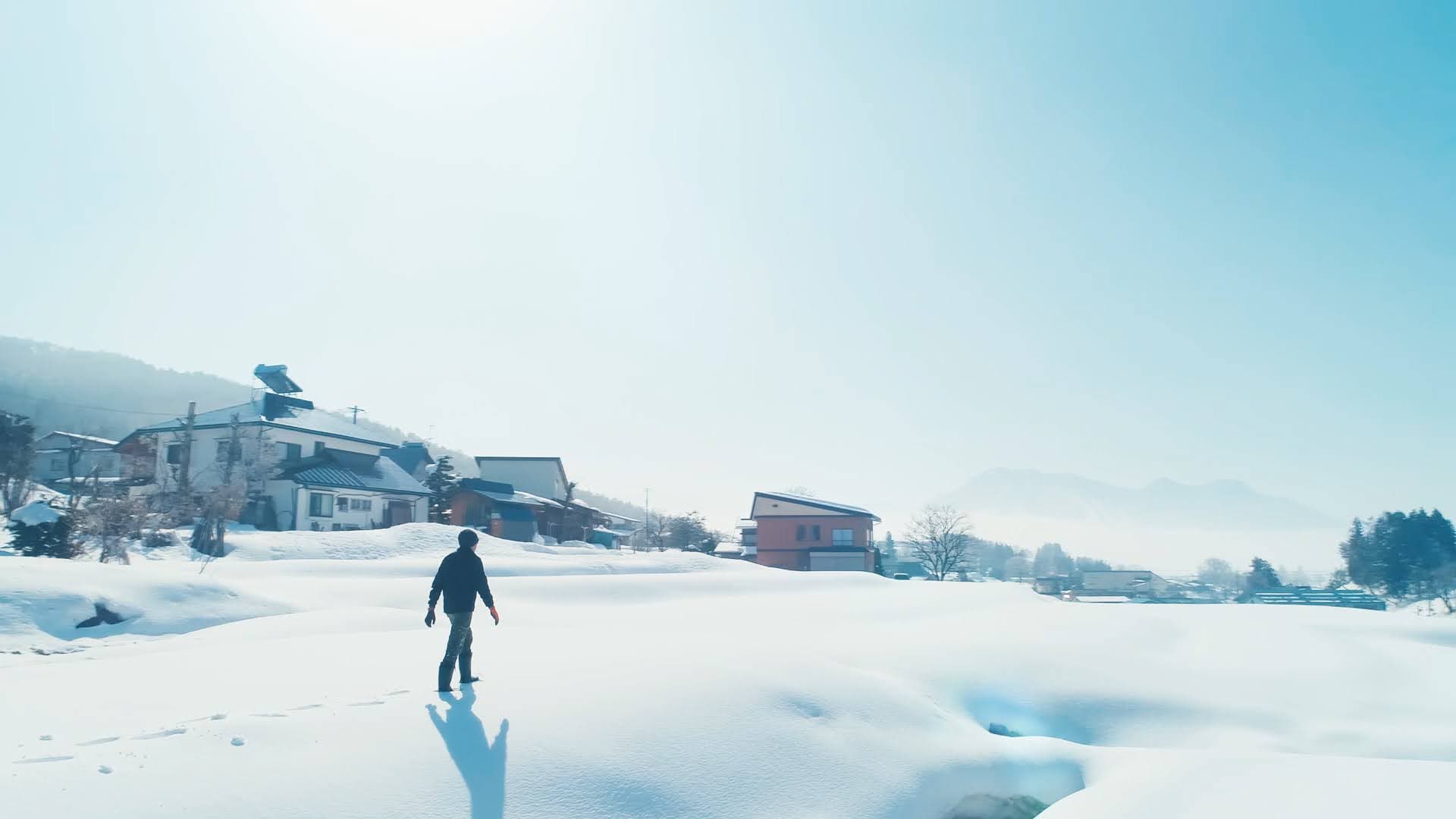

Smooth Japanese paper birthed by the snow in Nagano

Uchiyama paper was an important side business for farmers in the winter. Kozo, the raw material, is readily available in Nagano’s natural environment. Due to the high demand for durable paper for the paper sliding doors found in traditional Japanese homes, Japanese washi paper was actively hand-made whilst a manufacturing method was introduced in the Edo period. Farmers located in the north part of Nagano which has heavy snowfall, reap kozo during late November. One of the characteristics of Uchiyama paper is that exposing kozo over the snow and bleaching the kozo bark using ozone that generates when the snow melts. This special technique is truly the product of the harsh winter climate of north Nagano, and it is the secret to making plump and durable paper.The kozo skin that has been bleached through ‘snow bleaching’ is boiled and beaten until it becomes soft, and is carefully finished to a uniform thickness with expert technique. The strained paper is pressured to squeeze out the water and dry. The craftsmen’s patience and skill are poured into each process that is thoroughly carried out. In this way the Uchiyama Paper is shaped and cut according to the purpose and delivered to its final destination.

A tradition that lives on in the shadows

In the Meiji era (late 1800s), the manufacturing method was improved and production expanded. The Nagano Paper Industry Association was established. However, in the Taisho era (1900s), mass-produced Western paper began to spread, and the labor-intensive paper-making industry rapidly declined. Today, only a few craftsmen remain, and the tradition of Uchiyama Paper is at stake. Even so, Uchiyama Paper, which uses raw materials processed using snow, has the advantages of being resistant to sunburn, having excellent permeability, and toughness. Its use is not limited to only writing paper, but also has outstanding functions within the house as paper sliding doors and lighting equipment. Uchiyama paper, filled with the wisdom of the ancestors utilizing the harsh natural conditions of heavy snowfall, colors lives as a product that can be maintained and used for a long time.